(2) Complete 4-wide Belshaw Donut Lines from Mixing to Packaging

Description

(2) Belshaw Complete Donut Lines - Mixing to Packaging. (Yeast raised/Cake donuts)

Mixing and Proofing

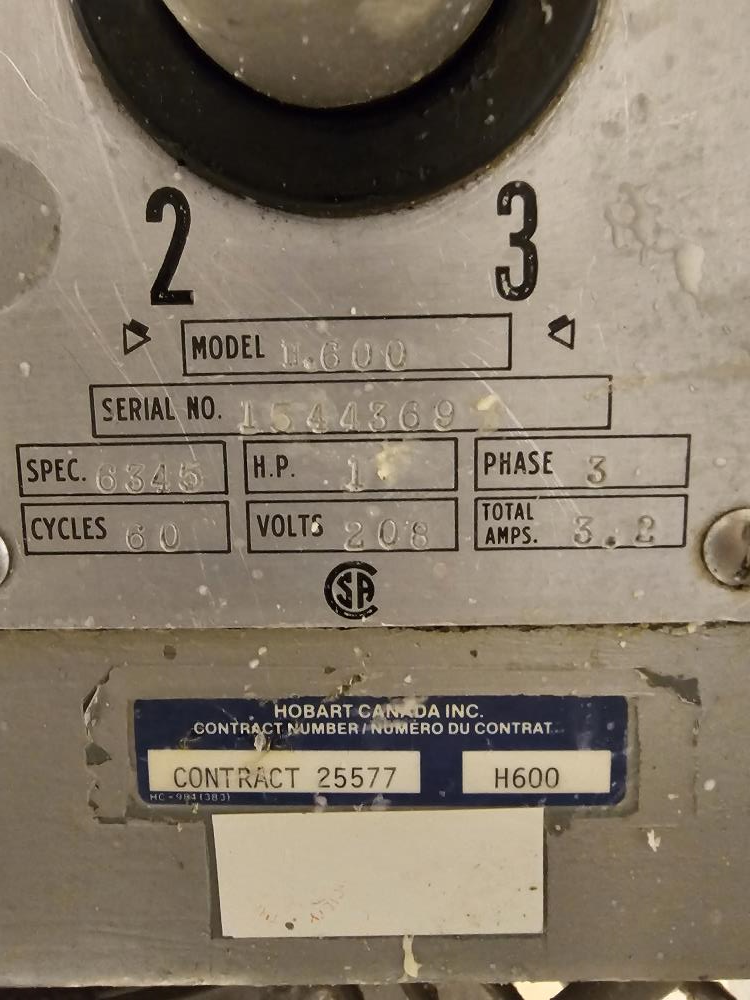

(2) - Mixers, Hobart 60 Qt and Esmach Model ISE/130F spiral mixers. (3) Rack proofers, Bakers Aid, Cinelli, and Nicholson Proofers.

Line 1

Belshaw Century 400G Donut fryer, w/ submerged conveyor, SS infeed sheeting table w/ Belshaw Multi-Matic 4-head cake drop depositor package. Heated glaze application system with wire belt conveyor, recovery tank and return pump. Misc. transport conveyors to a 10-tier spiral cooling conveyor w/ wire mesh belt. Multi level back and forth cooling conveyor with blast freezer system. (Includes compressor and rooftop unit).

Line 2

Belshaw C400 Donut fryer, w/ submerged conveyor, SS infeed sheeting table w/ Belshaw 4-head cake drop depositor package. SS wire belt exit and transport conveyors, white plastic belt incline conveyor. Enclosed SS wire mesh spiral freezer. (Includes compressor and rooftop unit).

Packaging Equipment

(1) Shanklin A26A L-Bar Sealer w/ Shanklin heat tunnel, (1) Shanklin A27A L-Bar Sealer w/ Shanklin heat tunnel. (1) Fortress metal detector Model: CVF-5502, w/ retracting conveyor reject. (1) Top and bottom case taper.

Auxillary Equipment

Vemag Robot 500 w/ programmable guillotine cutoff. Adamatic hand operated half icer donut dipper. Moline Sheeting table, w/ roll over SS variable speed flour duster. SS fryer oil holding tank with pump. Dough Elevator. (3) Stand up Air compressors w/ extra compressed air tank.

Freezer storage

(2) Storage Freezers w/ rooftop units. Production Storage: Approx. 30 ft long x 19 ft wide x 10 ft tall. Shipping Storage: Approx. 32 ft. long x 25 ft. wide x 10 ft. tall.

***MORE PHOTOS AND INFORMATION UPON REQUEST***

- EACH LINE IS CAPABLE OF BELOW PRODUCTS AND PRODUCTION RATES:

- Ring donuts - 2oz. - 280 dozen/hr

- Bismarks - 2oz. - 280 dozen/hr

- Long Johns - 2oz. - 210 dozen/hr

- Apple Fritters - 3oz. - 180 dozen/hr

- Cake donuts - 1.75oz. - 280 dozen/hr

- Cake donuts - 2.75oz. - 240 dozen/hr

- Mini cake - 0.5oz. - 1000 dozen/hr

Specifications

Financing Options

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)